LNG Storage

1) Single containment LNG Tank: This type of tank consists of a single wall with insulation on the outer surface. The tank's inner surface is in direct contact with the cryogenic fluid. Single containment tanks are commonly used for land-based storage facilities. This type of tank is Ideal when land availability is not an issue, and this is the most economical and common solution for LNG storage. This type is typically designed with a primary liquid containment open-top inner tank, a carbon steel primary vapor-containing outer tank, and an earthen dike for secondary liquid containment.

2) Double Containment LNG Tanks: This type of tank consists of an inner and an outer wall with insulation in between. The outer wall acts as a secondary containment system and helps to prevent leaks or spills. Double containment tanks are commonly used for both land-based and offshore storage facilities. This type of tank has a secondary containment steel or concrete dike wall close to the vapor-containing outer tank. It is designed and constructed to contain possible loss of liquid from the inner tank but not to contain product vapor resulting from unlikely leakage. A double containment tank reduces land requirements and can provide additional resistance to external loads.

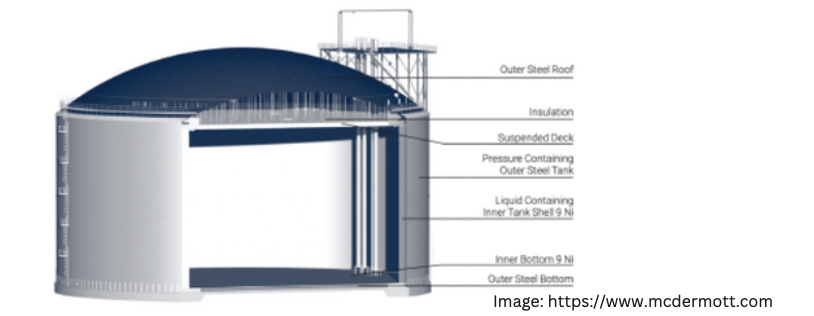

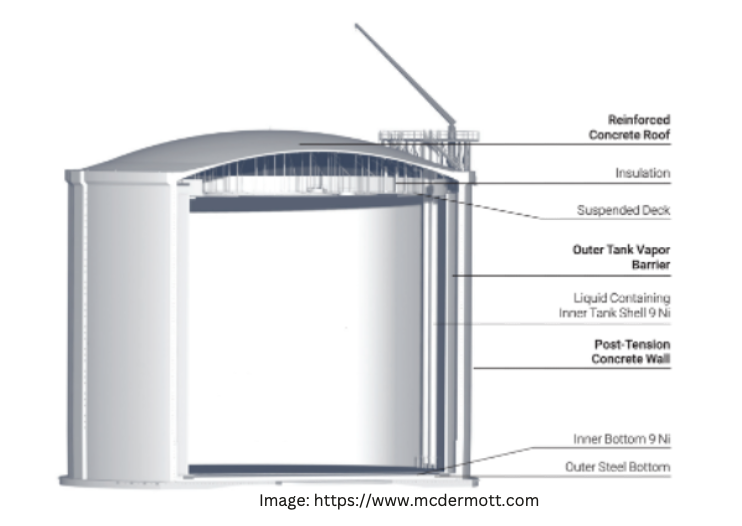

3) Full Containment LNG Tanks: This type of tank is similar to the double containment tank, but it has an additional outer wall that encloses the entire tank. The outer wall acts as a secondary barrier and helps to contain any leaks or spills. Full containment tanks are commonly used for large-scale storage facilities. The full containment storage tank is typically built with an open-top inner tank for primary liquid containment and a concrete outer tank for primary vapor containment and secondary liquid containment. In the event of a leak, the outer tank can contain the liquid and release the vapor in a controlled manner. This design reduces land requirements and provides additional resistance to external loads, making it suitable for use on tight sites or when regulatory or customer requirements mandate added resistance.

LNG Containment

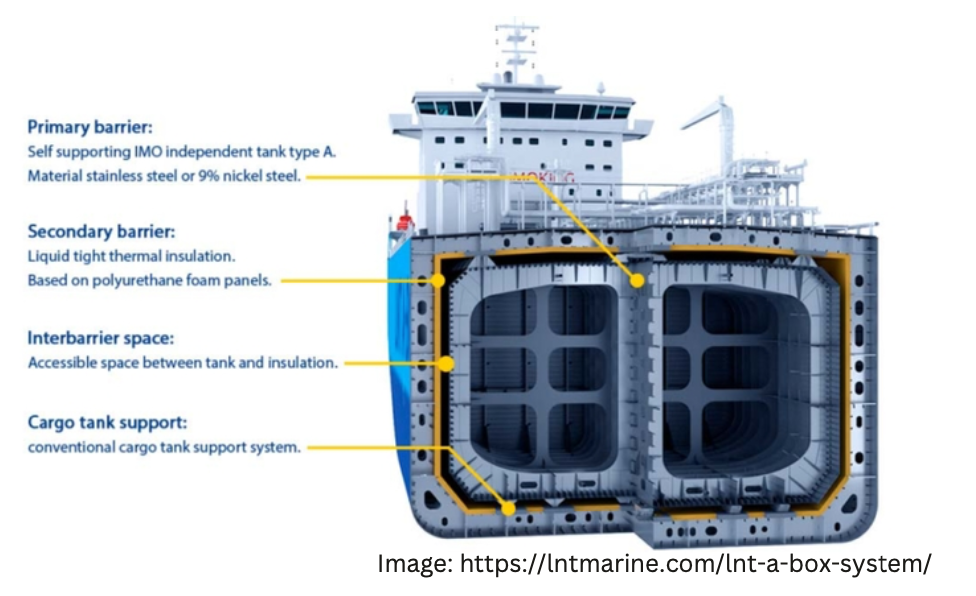

LNG (liquefied natural gas) is a cryogenic liquid stored and transported in specialized LNG containment systems. There are four commonly used types of LNG containment systems, each with its unique design and characteristics.

1) Freestanding solid-type structures

2)Non-freestanding (membrane) type:

b) Technigaz – TG Mark III: The TG Mark III tank is a non-freestanding, membrane-type LNG containment system that consists of a double-layered membrane made of reinforced polyurethane and a high-strength steel membrane supported by a steel structure. The tank is designed to be highly resistant to leaks and punctures and has a maximum capacity of up to 180,000 cubic meters. The TG Mark III tank is commonly used in LNG carriers and on- shore LNG terminals.

c) CS1: The CS1 tank is a non-freestanding, membrane-type LNG containment system similar in design to the GT 96 and TG Mark III tanks. It consists of a flexible membrane of synthetic materials supported by a steel structure. The CS1 tank has a maximum capacity of up to 200,000 cubic meters and is commonly used in LNG carriers and on-shore LNG terminals.

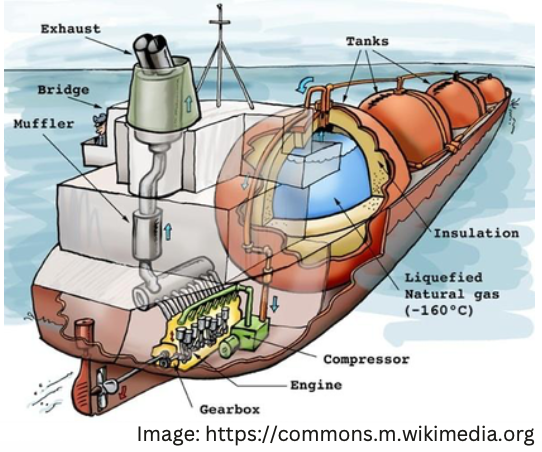

LNG Containment on the Vessel

LNG (liquefied natural gas) is transported across oceans and seas on specially designed ships called LNG carriers. These vessels are equipped with LNG containment systems that ensure LNG's safe storage and transportation. Two commonly used types of LNG containment systems on ships are Moss and membrane.

Moss Containment System:

The Moss containment system is a spherical LNG tank named after its inventor, Norwegian engineer Oscar Moss. The tank comprises a single steel membrane with insulation materials and is supported by a steel skirt. The tank is designed to be highly durable, able to withstand the ship's extreme weather conditions and movements, and can store up to 200,000 cubic meters of LNG. The system also includes a gas management system that regulates the pressure and temperature of the LNG, as well as a vapor recovery system that captures and re-liquefies the boil-off gas generated during transportation.

Membrane Containment System:

The membrane containment system is a type of non-freestanding LNG tank consisting of a flexible membrane of synthetic materials supported by a steel structure. The membrane is designed to be highly durable, able to withstand the ship's movements and extreme weather conditions. It can expand and contract depending on the volume of LNG it contains. The system also includes a gas management system and a vapor recovery system.

The membrane containment system is commonly used in smaller LNG carriers and is more space-efficient than the Moss containment system, allowing for more flexibility in ship design. One of the advantages of this system is that it can be easily repaired or replaced if damaged without the need to replace the entire tank.