Field Development

Development begins when it is determined by oil layer and gas layer investigations that commercial production is viable. This involves the design and building of oil and gas processing systems, pipelines, storage and offloading facilities, and production well drilling. When a big gas field is developed, the site is also evaluated for liquefied natural gas (LNG) development. LNG projects necessitate large-scale liquefaction plants and exporting infrastructure, necessitating the establishment and maintenance of long-term client connections.

The development stage occurs after successfully completing the field discovery and field assessment phases and prior to the start of field production. Field Development Plans (FDPs) provide the necessary assistance for field optimization by incorporating all actions and processes required to develop a field optimally.

- Geologists, geophysicists, and reservoir engineers must develop a precise Field Development Plan (FDP).

- Determine the optimal location and design for production/injection wells - drilling engineers, reservoir engineers, and geologists.

- Choose the best production facilities for properly processing hydrocarbons before treatment - production engineers, reservoir engineers, and facilities engineers.

- Logistics engineers select the transport choices and routes for exporting oil and gas.

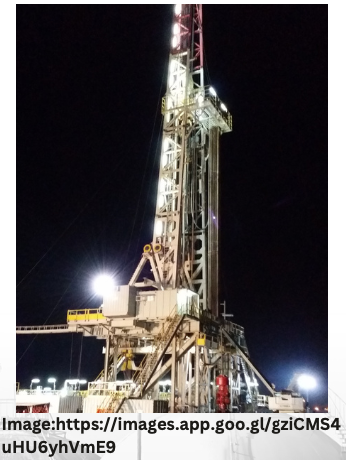

Drilling

As the well is drilled, the casing is installed to reinforce the walls of the wellbore and prevent it from collapsing. Once the well reaches its target depth, the drill bit is removed, and the well is completed. Completion involves installing production equipment such as tubing, pumps, and valves to bring the oil or gas to the surface.

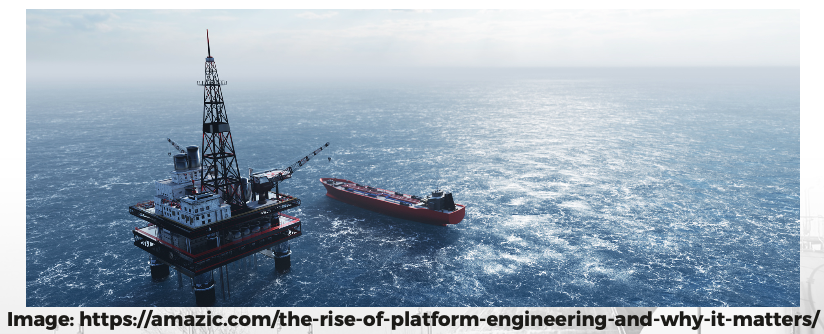

Within the drilling industry, there are primarily two methods: onshore and offshore drilling. Over the past two decades, the number of onshore drilling activities in the region has increased. Onshore drilling involves driving a rig deep into the ground to access fossil fuels, whereas offshore drilling occurs beneath the seabed. Apart from the utilization of distinct equipment, there are other notable differences between the two techniques.

onshore drilling is performed on land rather than over water, and the rigs are transported by ground vehicles. Moreover, at a single site, it is common for multiple wells to be drilled in close proximity to each other by slightly adjusting the position of the rig. Onshore drilling profiles vary from:

- Shallow to deep wells

- Extended reach to ultra-extended reach wells

- Vertical to deviated wells

Onshore drilling installations typically involve wells clustered together in a field, with varying densities depending on the resource being extracted. For heavy crude oil, a half-acre of land per well is typically used, while natural gas requires 80 acres of land per well. These wells are linked by carbon steel pipes that transport the oil and gas to a production and processing facility. At this facility, the oil and gas are subjected to chemical and thermal treatments. Compared to offshore rigs, onshore production firms can adjust their drilling activity more flexibly in response to market fluctuations.

Drilling is a critical component of the exploration process in the oil and gas industry. There are several types of drilling techniques used in exploration, including:

- Conventional drilling: This involves drilling a vertical well from the surface to reach a target depth where oil or gas may be present. Conventional drilling is a prevalent drilling method used in the industry, suitable for different types of geological conditions.

- Directional drilling: This technique is used when the target depth is not directly beneath the surface location of the drilling rig. Directional drilling involves drilling at an angle to reach the target, which can be located several miles away from the drilling location. With this technique, exploration companies can access resources that would be difficult or impossible to reach with traditional drilling methods.

- Horizontal drilling: This technique involves drilling a wellbore horizontally through the target formation, which can allow for greater contact with the oil or gas reservoir. Horizontal drilling is often used in combination with hydraulic fracturing to increase production rates.

- Extended reach drilling: This technique involves drilling a wellbore at an extreme angle or curve, allowing exploration companies to access resources that are located far from the drilling location. Extended-reach drilling is often used in offshore drilling operations, where it can be difficult to position a rig directly over the target location.

- Coiled tubing drilling: This technique involves using a continuous length of tubing to drill a wellbore. Coiled tubing drilling is often used for smaller-diameter wells or to access hard-to-reach locations.